(ORIGINALLY PUBLISHED IN SNACK FOOD AND WHOLESALE BAKERY – ONLINE)

The term silo has been with us a long time. It goes back to the Latin sirus which, in turn, comes from the Greek word siros. It originally meant a pit or underground place for keeping grain.

In industry, silos have become the guardians at the gates of many manufacturing plants – the first thing you see looming above the roof line as you approach the facility.

Rising as much as sixty feet and higher, silos are used to store bulk quantities of manufacturing materials. In the snack food and baking industry, the most common items stored in silos are grains, various flours, and sugar.

Silos offer a lot of advantages:

- No pallets of bagged material to unload and store at the warehouse.

- No need to tear open one 50-100 lb. bag after another and dump the contents into a hopper – and then clean up the overspray and deal with the empty bags.

- By simply opening a valve, the rate and amount of material can be regulated as it flows continuously from the silo into the manufacturing process.

However, as it is with most solutions, silos require a little maintenance of their own or they become problems, too. At the top of the list of concerns is food safety and quality.

Wherever flour and sugar congregate, various members of the animal and plant kingdom like to capitalize on the opportunity for a quick, and often abundant, meal. This includes rodents, insects, bacteria, and mold.

The chief insect invaders of flour silos are the Red Flour Beetle and the Confused Flour Beetle. These bugs, each about 1/8-inch long, look so similar that it is believed that is how the Confused Beetle got its name – it is so easy to confuse it with a Red Beetle. One difference is the Red Beetle can fly. Both breed heavily in the warmer months.

The Confused Beetle is the number one insect pest in American flour mills. And it’s an old pest. It’s been found in a jar that likely contained flour in a tomb of the pharaohs from around 2500 B.C. When present in large numbers, they can turn the flour grayish and cause it to mold more quickly. They also give the flour an unpalatable taste and odor from secretions of their scent glands.

One client told us, “The Confused Flour Beetle has a 28-day cycle from egg to adult. If our silo isn’t regularly cleaned approximately monthly and if there’s infestation they might nest in something like a gasket. Then they get very prolific in that area.”

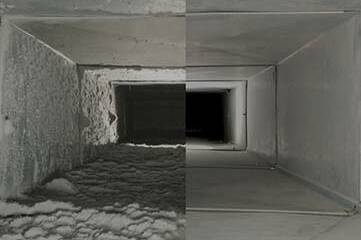

Mold is another major concern. When silos are not cleaned regularly, there is a high likelihood of mold buildup. This is commonly visible as shades of green and black in the flour, particularly on the inside walls. It can get as bad as an inch-thick (or more) layer of greenish flour clinging to the walls.

Mold growth is facilitated by the presence of moisture, which can precipitate when warm flour is pumped into a silo and cools down. Dehumidifiers can help guard against this problem.

To avoid many of these issues, silos are usually put on a routine cleaning schedule. The frequency of cleaning can vary tremendously from every month to yearly, depending on local weather conditions, what’s being stored, how often the silo empties, and simple common sense and experience.

A Quality Maintenance Program

Doug Nakamura is the director of operations for Upper Crust Enterprises of Los Angeles, America’s first manufacturer of “panko” or Japanese breadcrumbs. He outlined the steps his company routinely takes to keep their flour silos in top shape.

“We clean our silos twice a year and fumigate after each cleaning,” Nakamura said. “We also change our filters monthly. Plus we have our own self-audit, through our HACCP system (Hazard Analysis and Critical Control Points). Lastly, we hire a third party auditor to perform a routine review.”

This is in addition, of course, to standard inspections by the FDA and health department.

Finally, Nakamura ensures that a system of precautionary measures are in place, including:

- Buying from a reputable flour manufacturer.

- Getting a certificate of analysis for every load.

- Ensuring that the flour delivery trucks are inspected weekly.

- Inspecting the hoses and unloading mechanism on each truck.

- Ensuring the piping is kept locked.

The Cleaning Process

Silos can be cleaned by a number of methods, but in most cases, the process involves brushing down the sides of the interior and/or scraping them as needed. To avoid scratching the surface and to prevent sparking, plastic scrapers may be needed.

Although simple in principle, the work takes some practice and preparation.

Safety has to come first because multiple hazards exist, including falls, explosions, lack of oxygen, and “drowning” in liquid or finely-milled products like flour and sugar. A silo is an OSHA-defined “confined space,” meaning that workers in it have to follow standard safety procedures for enclosed areas with inherent hazards.

Proper breathing precautions must be considered where dust, volatile chemicals or oxygen scarcity can occur. Sometimes this is learned the hard way. Our firm was caught off guard once when we had a worker steam cleaning a massive vat that had held cooking oil. Steam vapor replaced the breathable air and literally lifted the available oxygen above his head. Fortunately, the matter resolved quickly, but it was a lesson in the importance of trying to anticipate the unexpected.

Food storage silos typically have platforms or “cages” built in at the top so workers have access for cleaning and servicing. These have to be treated with respect. Although it happens rarely, these cages can have breaks in them that can be hidden by a coating of flour or sugar. A worker should fully inspect these and ensure he’s wearing a harness and lifeline before stepping onto such an apparatus.

Sometimes you find no cage at all. It’s simply open space at the top. In this case, a worker will need to drop down from the top in a “bosun’s chair,” a chair on a rope that is lowered down. It may have a motor or be controlled by hand at the chair. Even eighty-foot silos may need to be cleaned this way. Any time a bosun’s chair is used, it is secured on the outside of the silo and OSHA safety standards are adhered to.

Such specialized equipment, preparations and OSHA requirements prompt many companies to hire outside firms to clean their silos. It saves a lot of headaches. But some plants still prefer in-house cleaning. Whatever method is used to clean, an opening at the top of the silo is vital for access and, sometimes, ventilation. An opening at the bottom is equally critical for draining out product which has been cleaned from the silo. In some instances, there are no access doors at either end and they have to be installed.

Vacuuming is a common method of cleaning debris from the bottom. However, this can stir up a lot of static electricity around certain materials such as flour. Visible sparks can occur. A way to reduce this risk is to attach wooden poles to vacuum hoses to ground them.

Silos are normally cleaned without water. When the stored product is easily dissolved, such as sugar or syrup, wet washing may be the method of choice. This approach may take longer (sometimes it’s faster) because it requires more prep work and attention to water drain-off. It also means the silo must dry out and this can cost production time. Moisture attracts mold so that is another consideration. Needless to say, the silo needs to dry thoroughly before it is refilled.

In some instances wet cleaning is the only method available. As an example, if a flour silo needs welding, all combustible material must be removed and this may only be achievable through wet washing.

Additional Issues

Food product storage silos are lined with a coating that can deteriorate over time. Flaking or rusting can contaminate the food product. This is commonly first noticed when particles show up in sifters. Some manufacturers re-coat their silo interiors every few years as a precautionary measure.

Breather bags at the top of the silo are another sensitive area. They permit filtered air in and out. Beetles can congregate in them. Small holes can permit insects to enter.

Leaks in a silo are, of course, a potential nightmare. A typical full capacity of about 130,000 pounds can be wasted from rain or dirt getting in. Water or air seepage should be looked for during any visual inspection.

Routine physical inspections can help spot such leaks. Another client, a tortilla manufacturer, regularly looks at gaskets, silo doors, and even under the silo on the conveyor line for flour leaks, insects, or rotten flour.

Summary

The checklist for any director of operations or sanitation should include a periodic inspection and cleaning of the silos.

Are you losing storage capacity because of buildup on the silo interior walls? This literally reduces the available diameter of the silo. It causes a silo to empty too quickly and costs more frequent visits from suppliers.

Are you in compliance with hygiene regulations? Could a lack of maintenance result in a food hazard, contamination problem, or God forbid, a production shutdown?

Are your silos being inspected periodically for issues like rain leaks, mold, or residue buildup? Routine visual checks can keep small problems from becoming big ones.

Ben Franklin wrote, “An ounce of prevention is worth a pound of cure.” A little attention to those quiet giants in your plant’s “back yard” can keep them working smoothly for you for years to come.